Electronics Chemistry

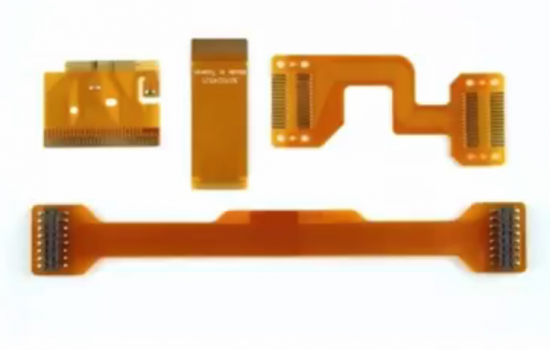

Flexible circuits were first introduced as a replacement for wire harnesses. The earliest versions date back to World War II. Today, flex and rigid flex circuits are filling an important role across multiple industries, include applications in the medical, automotive, and telecom fields.

Flexible circuits were first introduced as a replacement for wire harnesses. The earliest versions date back to World War II. Today, flex and rigid flex circuits are filling an important role across multiple industries, include applications in the medical, automotive, and telecom fields.

Today we are being asked by OEMs, particularly in the high-frequency space, for ways to minimize the amount of surface roughness to provide for enhanced electrical properties. Of course, when you minimize roughness you also run the risk of compromising the optimum adhesion of the smoothed material – especially if you don’t do any surface prep.

Today we are being asked by OEMs, particularly in the high-frequency space, for ways to minimize the amount of surface roughness to provide for enhanced electrical properties. Of course, when you minimize roughness you also run the risk of compromising the optimum adhesion of the smoothed material – especially if you don’t do any surface prep.

A beautifully registered multi-layer board, with nice drilled holes, level copper plating, and no evidence of separation. This is what we strive for in the manufacturing of printed circuit boards.

What finish should I use for my PCB Design? There’s no one single answer, it depends.

Mike Carano, RBP Vice President of Technology and Business Development leads a webinar to provide an overview of key technical issues driving changes in circuit board design and fabrication, including board thickness and HDI; line width and spaces, via structure and other measurements being driven by the trend toward miniaturization; trends in materials; printed electronics; and today’s biggest technical challenges.

Reliability Fundamentals: Failure Mechanisms and Success Through Process Modifications

Michael Carano

RBP Chemical Technology

Article summary

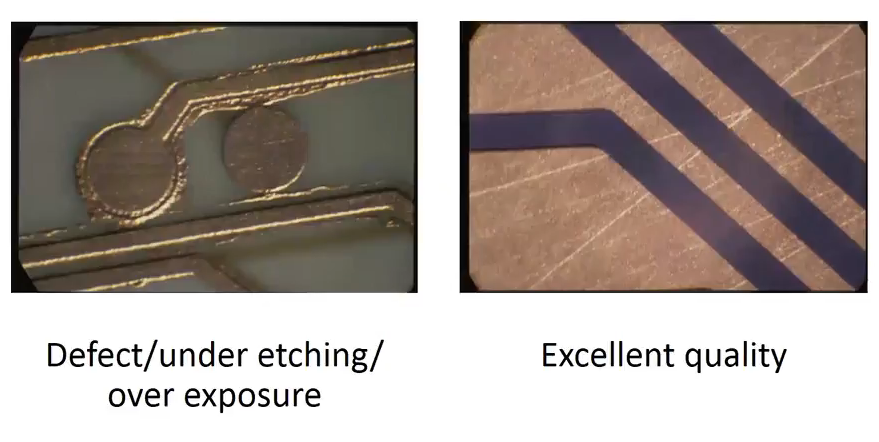

The photoimaging process is one of the first steps in the PCB fabrication process. In order to insure that the image of the circuitry conforms as close to the desired design as possible (i.e. lines and spaces), surface preparation of the copper foil surface is one of the critical success factors. Employing the optimum mix of surface cleaners and microetchants will provide a clean surface with sufficient surface area to promote dry film adhesion. The fabricator has numerous options and should determine the optimum process by accounting for the type of copper foil used as well as the classes of soils to be removed.

Introduction

There are several options available. In addition to pumice and aluminum oxide surface preparation, chemical cleaning as a means to insure optimum photoresist adhesion has gained significant popularity. In this ca

As a supplier of HAL fluxes to the circuit board industry, RBP Chemical Technology® researchers were very aware of the drawbacks of conventional, halide-based products. High corrosivity, frequent equipment maintenance, time-consuming solder skimming, deficiencies in solder coverage, dull solder and environmental issues all led our product development team to find a better, more reliable product for the HAL process.

More and more board shops are interested in running the tin stripper on a feed and bleed system. This method gives more consistent performance and reduces the downtime for dumping and changing the solution. The system can be controlled either by specific gravity or panel count as illustrated in the charts below.