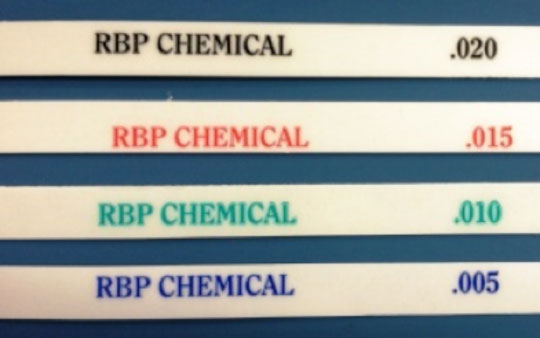

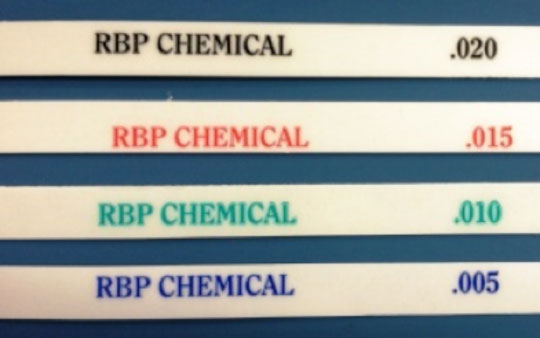

Plate Shims

| PART # | DESCRIPTION |

|---|---|

| SP0042 | SHIM, .005″ RBP |

| SP0043 | SHIM, .010″ RBP |

| SP0044 | SHIM, .015″ RBP |

| SP0045 | SHIM, .020″ RBP |

| PART # | DESCRIPTION |

|---|---|

| SP0042 | SHIM, .005″ RBP |

| SP0043 | SHIM, .010″ RBP |

| SP0044 | SHIM, .015″ RBP |

| SP0045 | SHIM, .020″ RBP |

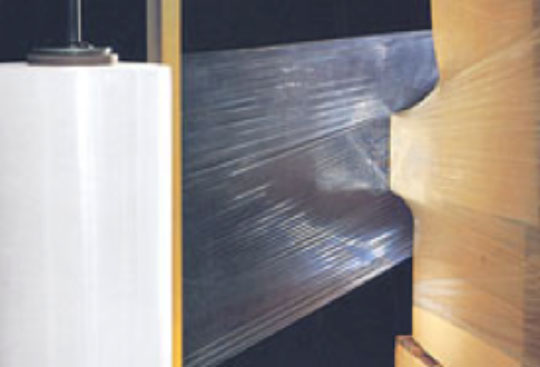

We carry a full line of Cast or Blown, Machine or Hand.

| SKID WEIGHT | FILM GUAGE |

|---|---|

| Up to 4,000lbs. | 120 |

| Up to 3,000lbs. | 90 |

| Up to 2,500lbs. | 80 |

| Up to 2,000lbs. | 70 |

| Up to 1,600lbs. | 60 |

| CAST | BLOWN | MICRON | |

|---|---|---|---|

| Clarity | Excellent | Good | Excellent |

| Cling | Good | Excellent | Good |

| Noise Level | Quiet | Loud | Quiet |

| Elongation | High | High | Minimal |

| Puncture Resitance | Good | Excellent | Good |

| Load Retention | Good | Excellent | Good |

| Attributes | Quiet, Clear. Recommended for Uniform Loads. | Puncture Resistant. Recommended for Irregular Loads. | Puncture Resistant. More coverage with less film |

Please call 1-800-347-7377 for a quote.

A 100% recycled Kraft product developed specifically for use in newspapers as underwrap for newspaper bundles.

| PART # | DESCRIPTION |

|---|---|

| MS0034 | BOTTOMWRAP 40# 13.5 X 18 |

| MS0042 | BOTTOMWRAP 40# 13.5 X 21 |

| MS0018 | BOTTOMWRAP 40# 13.5 X 23 |

| MS0074 | BOTTOMWRAP 40# 13 X 22 |

| MS0064 | BOTTOMWRAP 50# 13 X 23 |

| MS0070 | BOTTOMWRAP, 40# 12 X 20 |

| MS0072 | BOTTOMWRAP, 40# 13 X 23 |

| MS0071 | BOTTOMWRAP, 50# 13 X 18 |

| MS0058 | BOTTOMWRAP, 40# 13 X 21 |

Custom sizes available upon request

|

Looking to outsource your chemical manufacturing or blending? Catch up on latest webinar.

|