Failure of an implanted medical device is not an option.

As your trusted partner - no matter the device metal, geometry, or complexity - you can count on us to deliver chemical processes that provide consistent, repeatable, and reliable results safely and efficiently.

Eliminate Your Imperfections

Discover how our chemistry & experts are right for you

Medical implantable devices must have clean and pristine surfaces, and that’s achievable with chemical solutions by RBP Chemical Technology. For nearly 20 years, RBP has assisted the medical industry with surface chemistry solutions for cleaning and passivation of implanted medical devices.

Full Line of Medical Device Chemistry Products

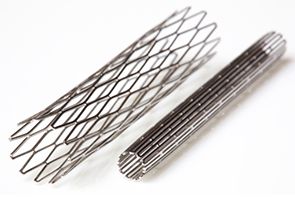

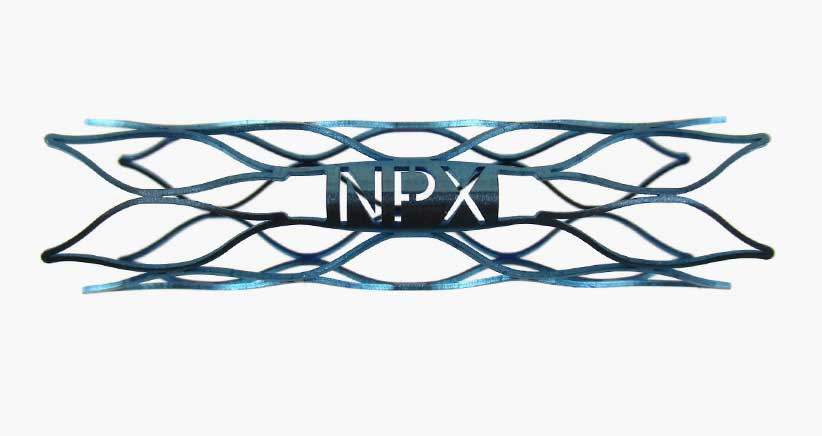

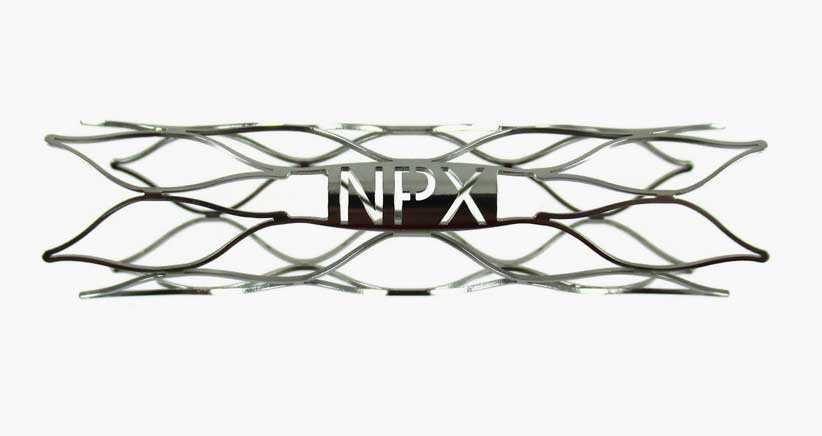

Our chemists are leaders in innovating comprehensive chemical solutions to clean, deoxidize, electropolish and passivate medical implantable devices.

Learn more.

Groundbreaking Room Temperature Electropolishing

Excellent alternatives to typical low temperature EP media for Nitinol, RBP’s room temperature electropolishing solutions are comparable in performance and extremely easy to use.

Learn more.

Direct Collaboration and Consultations

Unique challenges require custom solutions, and custom is where RBP excels. Our team of chemical engineers will work directly with you, develop an understanding of challenges, and formulate a solution that meets your needs.

Learn more.

Environmental Health and Safety Expertise

As experts in chemical handling and process safety, we work with you to identify ways your team to use chemicals safely and responsibly – minimizing the risk of fires, accidents, fines, injuries and even deaths.

Learn more.

Save Time and Money with Toll Blending

Outsourcing your chemical blending needs to RBP is a simple, turnkey process that provides you with superior chemical solutions for your medical implant devices while creating significant cost savings for your bottom line.

Learn more.

Resources

As a company that produces chemistry with a wide range of features, we know how important it is to highlight the benefits of each one. That's why we frequently release visual content that helps customers understand what makes our products superior.

VIDEOS

We’ll provide samples so you can test on your devices.

What Our Customers Have to Say

Get Started

15-MINUTE VIRTUAL

CONSULTATION

Join our team of chemists and experts via Microsoft Teams to conduct “discovery” of your chemistry process opportunities and challenges.

SEND US YOUR

PARTS/PROTOTYPES

We specialize in running your sample parts or prototypes through our in-house chemistry line to find the best solution so you can develop your process.

Solutions & Resources

| Product | Description | HF? | Strong Acid? | Inhibitors? | Relative rate of attack on bare metal, 1 (low) - 7 (high) | Operating Temp Range (°C) |

|---|---|---|---|---|---|---|

| MicroClean™ Ti | Degreaser+, designed to remove soils that could interfere with subsequent processes | 0 | 25 - 70 | |||

| Ti Pickling Solution™ | Mildly acidic, free of hydrofluoric acid | 1 | 20 - 50 | |||

| MicroClean™ 2150 | Moderately acidic, free of hydrofluoric acid | 2 | 20 - 50 | |||

| MicroClean™ 2160 | Moderately acidic, free of hydrofluoric acid | 2 | 20 - 50 | |||

| MicroClean™ EV3 | Strongly acidic, free of hydrofluoric acid | Yes | 3 | 15 - 50 | ||

| MicroPolish™ II | Strongly acidic, with hydrofluoric acid, inhibited, mild polishing action, relatively less aggressive | Yes | Yes | Yes | 4 | 15 - 50 |

| MicroPolish™ | Strongly acidic, with hydrofluoric acid, inhibited, mild polishing action, relatively more aggressive | Yes | Yes | Yes | 5 | 15 - 50 |

| ChemPolish Ti6Al4V™ | Strongly acidic, with hydrofluoric acid, inhibited, more aggressive | Yes | Yes | Yes | 6 | 15 - 50 |

| MicroClean™ MV | Strongly acidic, with hydrofluoric acid, inhibited, more aggressive | Yes | Yes | Yes | 7 | 15 - 50 |

| MicroClean™ BS | Strongly acidic, with hydrofluoric acid | Yes | Yes | 8 | 15 - 50 |

| Product | Description | Room Temperature? | Viscosity | Conductivity | Flammability |

|---|---|---|---|---|---|

| Nitinol ElectroPolish™ | Standard electropolish containing 70% Methanol/ 30% Sulfuric Acid; this product requires cooling to very low temperatures | higher (at low temp) | higher | higher in storage, lower at low temp | |

| ElectroPolish NF™ | Room temperature electropolishing chemistry, organic | Yes | higher | lower | lower |

| ElectroPolish Ti2™ | Room temperature electropolishing chemistry, organic | Yes | lower | lower | lower |

| ElectroPolish 2152 | Room temperature electropolishing chemistry, organic | Yes | lower | higher | higher |

Cobalt Chrome

| Process Step | Product | Description |

|---|---|---|

| Step 1: Pre-Clean | MicroClean™ Ti | Degreaser+, designed to remove soils that could interfere with subsequent processes |

| Step 2: Deoxidize | CoCr Cleaner™ | Strongly acidic, for light oxide |

| Step 2: Deoxidize | CoCr Cleaner™ II | Enhanced re-formulation of our CoCr Cleaner that provides a unique chemical portfolio for enhanced efficacy. |

| Step 2: Deoxidize | Alkaline Descale™ | A strongly oxidizing surface conditioner designed to descale cobalt/chromium and other chromium based alloys before chemical polishing or electropolishing |

| Step 2: Deoxidize | Descale Remover™ | An acidic chemistry that removes smut and residual metal oxide solubilized by Aklaline Descale |

| Step 3: Electropolish | CoCr Electropolish | Acidic electropolish chemistry |

Stainless Steel

| Process Step | Product | Description |

|---|---|---|

| Step 1: Pre-Clean | MicroClean™ Ti | Degreaser+, designed to remove soils that could interfere with subsequent processes |

| Step 2: Clean | ChemPolish™ RL | Acidic chemistry for cleaning, polishing and passivating 300 series stainless steel |

| Step 2: Clean | ChemPolish™ SS | Acidic chemistry for polishing and passivating 300 series stainless steel |

| Step 3: Electropolish | ElectroPolish 4000™ | Wide operating parameter general use electropolish chemistry. |

| Step 3: Electropolish | ElectroPolish 5000™ | Acidic electropolish chemistry |