What to Know About Cleaning, Deoxidizing, Passivating and Polishing Medical Implant Devices

To ensure the effectiveness of medical implant devices it is essential that manufacturers correctly clean, deoxidize, polish and passivate these devices. Here is some relevant background pertaining to these processes.

Cleaning Medical Implant Devices

Cleaning of parts prior to subsequent key steps in surface finishing is important because the surfaces need to be free of organics. This ensures a device is ready for deoxidation and electropolishing. Many times, using a simple degreaser/cleaner like Alconox will work just fine. Other times, however, there is a need for a more specialty cleaner. This is especially true in situations where organics are embedded in the part. For this situation, we recommend using our Microclean Ti. It should be noted that not all cleaning tasks are the same. It truly depends on the surface. And sometimes parts are quite clean to begin with.

Deoxidizing Medical Implant Devices

The deoxidizing (or etching/pickling/descaling) step strongly depends on the material. Whether it is titanium or Cobalt Chrome makes a big difference. Many view titanium as a material that’s easy to deoxidize, Cobalt Chrome on the other hand can be very difficult to deoxidize. Nitinol is usually somewhere in between. But it depends strongly on the heating history of the part and its dimensional tolerances.

When it comes to deoxidizing medical implant devices and the selection of a deoxidizing chemistry, here are a few questions you should consider. How many shape setting steps has the part gone through and what was the equipment to accomplish that shape setting? What type of heating and in what atmosphere? Whether the oxide is uniform and thin or multilayered and thick? All this makes a difference.

Chemistry Selection for Deoxidizing Medical Implant Devices

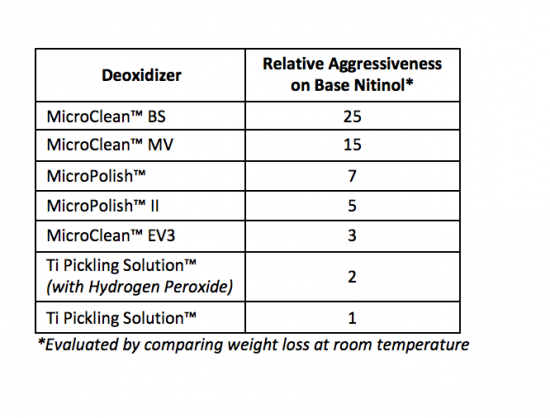

Different chemistries can be used to deoxidize devices made of Nitinol. Major considerations include safety concerns and chemistry aggressiveness. Hydrofluoric acid is a common active ingredient in deoxidizers. Typically it is present at low concentrations but some manufacturers prefer not to work with such chemistries. Fortunately, non-hydrofluoric acid chemistries work well in many cases. When more aggressive chemistries are required, their activity can be controlled not only by adjusting concentrations but also by using inhibitors. Then, process conditions, including time, temperature and use of sonication allow to establish an optimized procedure. This complete toolbox allows development of a viable process for virtually any medical device.

Electropolishing Medical Implant Devices

Electropolishing is an educated art. You need preparation and you need know-how, however, it’s still an art. Effective electropolishing of medical implant devices comes with experience. Electropolishing is generally more established for Stainless Steel because it has been used on SS for many years on industrial parts of all types and sizes. Chemical formulations are also relatively well established for SS. Electropolishing medical implant devices is still a newer process even for SS, and especially for Nitinol devices. The most common chemistry for electropolishing Nitinol is the 70% methanol/30% sulfuric acid mix used at very low temperatures. But there are room temperature alternatives, the so-called room temperature electropolishes. Another element is process equipment: an electropolishing cell, chiller, power supply and fixtures. In general, blueprints are non-existent and processes are developed for specific needs.