Welcome to the RBP Chemical PCB troubleshooting corner. We regularly send out email updates.

PCB Troubleshooting

One of the main causes of plating defects is copper peeling. Copper peeling is really a disconcerting situation. If it happens, you’ve already put a lot of money, time, and effort to fabricate the circuit board up to this point as you come out of your electrolytic, or electroless copper, plating process. This becomes disconcerting because you may find out that the plated copper peels from either the laminate surface or from the electrical surface. Of course at that point, it’s very difficult to rework the board, and most likely that board at this time will be most likely scrapped.

Are all OSPs the same? And how does an OSP actually protect the copper base?

Let’s talk about hot air leveling, and of course, lead-free hot air leveling. If you’ve spent time in Asia and Europe, you’ll notice that in North America, the final finish market is still significantly different than it is in Asia and in Europe. Particularly in Asia, where they have moved away significantly from hot air leveling. Less than three percent of circuit boards made in Asia now use hot air solder leveling, or even lead-free hot air solder leveling. Whereas in North America, we’re still seeing a good portion, 35 to 40 percent of the circuit boards, using some type of hot air leveling, whether it be lead-free or lead based. Why is that? Hot air leveling has many advantages and disadvantages. Below we will highlight some of these advantages and disadvantages.

Etchback and desmear serve many purposes. The first purpose of etchback is to assure the copper is clean. Assuring the copper is clean will then help form a metallurgical bond with the plating. The last purpose of etchback is to form a three-point contact around the inner layer. Why are each of these processes so important? Below we will go in more depth as to how each process effects the overall goal of etchback.

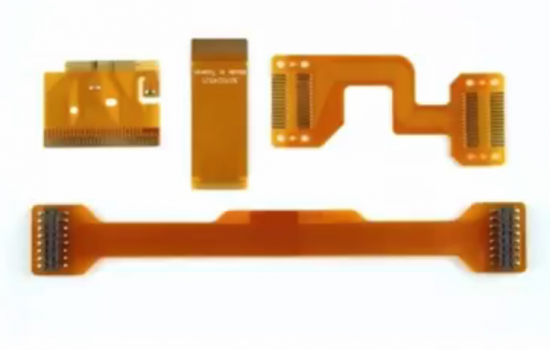

Flexible circuits were first introduced as a replacement for wire harnesses. The earliest versions date back to World War II. Today, flex and rigid flex circuits are filling an important role across multiple industries, include applications in the medical, automotive, and telecom fields.

Flexible circuits were first introduced as a replacement for wire harnesses. The earliest versions date back to World War II. Today, flex and rigid flex circuits are filling an important role across multiple industries, include applications in the medical, automotive, and telecom fields.

Today we are being asked by OEMs, particularly in the high-frequency space, for ways to minimize the amount of surface roughness to provide for enhanced electrical properties. Of course, when you minimize roughness you also run the risk of compromising the optimum adhesion of the smoothed material – especially if you don’t do any surface prep.

Today we are being asked by OEMs, particularly in the high-frequency space, for ways to minimize the amount of surface roughness to provide for enhanced electrical properties. Of course, when you minimize roughness you also run the risk of compromising the optimum adhesion of the smoothed material – especially if you don’t do any surface prep.

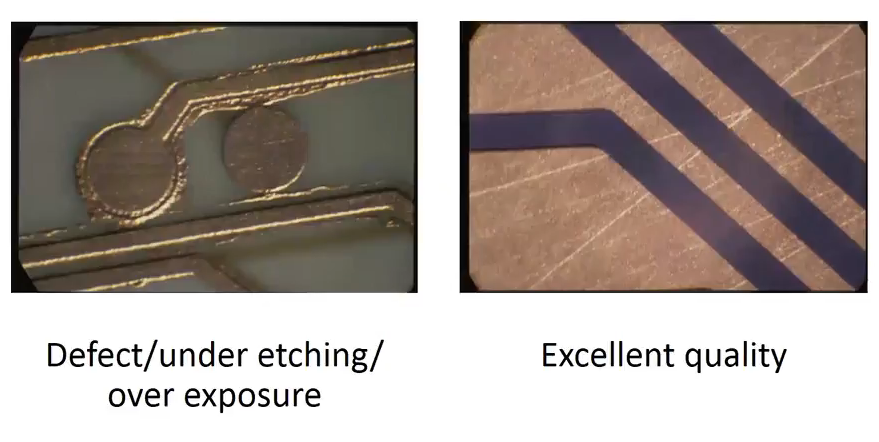

A beautifully registered multi-layer board, with nice drilled holes, level copper plating, and no evidence of separation. This is what we strive for in the manufacturing of printed circuit boards.