Technical Capabilities

Chemistry plays a vital role in medical device manufacturing, ensuring that products are safe, durable, and effective. From sterilization to enhancing materials and ensuring regulatory compliance, chemical processes are critical at every step of device production. As the medical device industry faces increasing regulatory pressure and demand for innovative solutions, chemical advancements are becoming more essential than ever.

A few years ago, a partner came to us with a difficult assignment. They were producing a mix of a volatile acid, something like 99% sulfuric acid with an alcohol solvent, in house. They needed to reduce the cost of producing and storing this chemical while also lowering risks to their employees.

A few years ago, a partner came to us with a difficult assignment. They were producing a mix of a volatile acid, something like 99% sulfuric acid with an alcohol solvent, in house. They needed to reduce the cost of producing and storing this chemical while also lowering risks to their employees.

Toll Blending is a common service for chemical companies (e.g.: “toll blender”) to manufacture/fulfill chemistry blending for a partner in order to reduce the partner’s production risks or capital investments. RBP Chemical Technology works with partners around the globe to provide this service, as well as, to optimize their chemical processes. Here are six reasons why customers turn to RBP for their toll blending needs.

When companies have specific chemical needs but lack the resources to address these needs in house, outsourced chemical blending – or Toll Blending – is a valuable solution.

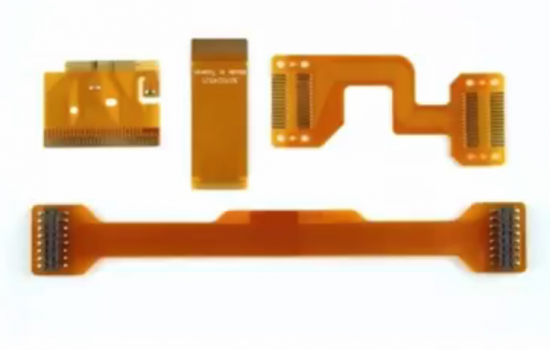

Flexible circuits were first introduced as a replacement for wire harnesses. The earliest versions date back to World War II. Today, flex and rigid flex circuits are filling an important role across multiple industries, include applications in the medical, automotive, and telecom fields.

Flexible circuits were first introduced as a replacement for wire harnesses. The earliest versions date back to World War II. Today, flex and rigid flex circuits are filling an important role across multiple industries, include applications in the medical, automotive, and telecom fields.

Today we are being asked by OEMs, particularly in the high-frequency space, for ways to minimize the amount of surface roughness to provide for enhanced electrical properties. Of course, when you minimize roughness you also run the risk of compromising the optimum adhesion of the smoothed material – especially if you don’t do any surface prep.

Today we are being asked by OEMs, particularly in the high-frequency space, for ways to minimize the amount of surface roughness to provide for enhanced electrical properties. Of course, when you minimize roughness you also run the risk of compromising the optimum adhesion of the smoothed material – especially if you don’t do any surface prep.

Meet the advanced troubleshooters who have spent their entire careers in the chemical industry and know RBP products inside and out. A unique source of customer support, they offer a thorough understanding of chemistry and unrivaled pressroom expertise. RBP’s technical service specialists are found not only problem-solving on the front lines, but also work diligently behind the scenes on new product development.