Enhancing Medical Device Manufacturing: RBP’s Specialized Chemistries for Implant Success

The medical device industry is one of the most demanding sectors, requiring precision, reliability, and innovation. Among its critical components are implants, medical devices designed to replace or support biological structures. Ensuring the functionality and longevity of these implants is paramount, and this is where RBP Chemical Technology’s expertise in specialized chemistries comes into play.

The medical device industry is one of the most demanding sectors, requiring precision, reliability, and innovation. Among its critical components are implants, medical devices designed to replace or support biological structures. Ensuring the functionality and longevity of these implants is paramount, and this is where RBP Chemical Technology’s expertise in specialized chemistries comes into play.

The Importance of Surface Treatment in Medical Implants

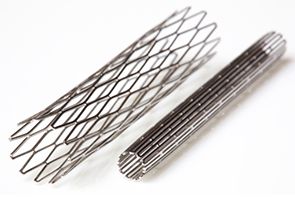

Medical implants must meet stringent performance and biocompatibility standards to ensure safety and effectiveness. Materials such as nitinol, stainless steel, titanium, and chrome alloys are commonly used due to their strength and corrosion resistance. However, these materials require precise chemical treatments to optimize their performance in the human body.

Surface preparation and finishing play a crucial role in implant manufacturing. Without proper chemical processing, implants may suffer from issues such as poor biocompatibility, corrosion, and mechanical failure. RBP’s proprietary chemistries address these challenges, enhancing implant quality in the following ways:

- Deoxidation & Passivation – Removing oxides and passivating surfaces is critical for preventing corrosion and ensuring implants remain inert inside the body. RBP’s chemistries effectively clean and passivate metals like stainless steel and titanium to meet FDA and ISO 13485 standards.

- Electropolishing & Surface Smoothing – Achieving a smooth, defect-free surface reduces the risk of bacterial adhesion and improves implant longevity. RBP’s electropolishing solutions refine metal surfaces, enhancing their aesthetic and functional properties.

- Coating & Adhesion Promotion – Some implants require specialized coatings for improved biocompatibility, durability, or drug delivery. RBP’s adhesion-promoting chemistries prepare implant surfaces for superior coating performance.

Efficiency and Consistency in Manufacturing

In addition to improving implant performance, RBP’s chemistries help streamline manufacturing processes. Consistency across production batches is vital for medical device manufacturers to meet stringent regulatory requirements. RBP’s solutions are designed to:

- Reduce Processing Time – Optimized formulations minimize the number of steps required in surface treatment, accelerating production cycles.

- Enhance Yield & Reduce Waste – By improving surface quality, RBP’s chemistries reduce rejection rates and material waste, lowering overall production costs.

- Ensure Regulatory Compliance – Medical device manufacturers must adhere to FDA, ISO, and ASTM standards. RBP’s products are engineered to meet these rigorous compliance requirements.

Partnering for Innovation in Medical Device Manufacturing

With decades of experience in specialty chemical formulation, RBP Chemical Technology continues to be a trusted partner in pushing the boundaries of medical device manufacturing. Our deep industry knowledge, combined with a commitment to innovation, allows us to continue to develop cutting-edge solutions tailored to the evolving needs of the medical sector.

Additional Resources:

- Learn more about passivation for medical devices: FDA Guidelines on Passivation

- Discover how electropolishing improves implant longevity: ISO 13485 Medical Devices Standard

- Explore RBP’s full range of chemical solutions: RBP Chemical Products

By leveraging RBP’s specialized chemistries, medical device manufacturers can ensure the highest standards in implant performance, regulatory compliance, and production efficiency, ultimately leading to better patient outcomes and enhanced industry reputation.