RBP Nitinol (NiTi) De-oxidizers and Etchants

Nitinol Deoxidize & Etch | Step 2 Surface Preparation

Processing Nitinol requires a carefully controlled sequence of chemical steps to ensure the alloy maintains its elasticity, biocompatibility, and mechanical performance. At RBP, we consider Nitinol Processing as a 4-Step Process:

Step 1 (Cleaning): Removal of surface residues to ensure uniform etching/polishing. Non-aggressive and effective on raw material post-processing soils.

Step 2 (De-Oxidize and Etch): Oxide removal with controlled removal and polishing of base metal. A variety of RBP deoxidizers exist for a variety of substrates and situations.

Step 3 (Electropolish): RBP’s Eps obtains a uniform polished surface that enhances corrosion resistance, reduces nickel ion release for better biocompatibility, and minimizes bacterial adhesion via surface cleanliness.

Step 4 (Passivation / Final Finish): Building a protective oxide layer to increase biocompatibility.

Each stage builds on the previous one, preparing the surface for the next transformation. From removing oils, to eliminating oxides and heat-affected layers, to achieving the final polished finish, every step plays a critical role in producing safe, reliable medical devices

Why Step 2 Is Critical in Nitinol Processing

Nitinol is one of the most advanced and sensitive alloys used in medical devices. Its performance (flexibility, elasticity, fatigue resistance) depends heavily on the condition of its surface.

Before a device can be electropolished, passivated, coated, or assembled, all oxides and heat-affected layers MUST be removed with control and consistency.

Step 2, Deoxidize & Etch, is where that transformation happens.

This step determines:

- How cleanly the material electropolishes

- Whether the surface becomes uniform or develops defects

- How well downstream finishes adhere

- Whether the device maintains dimensional accuracy

- The long-term corrosion resistance and biocompatibility

If Step 2 is unstable, everything downstream suffers.

That’s why Medical OEMs and contract manufacturers rely on chemistry that is predictable, gentle on Nitinol, and proven in production.

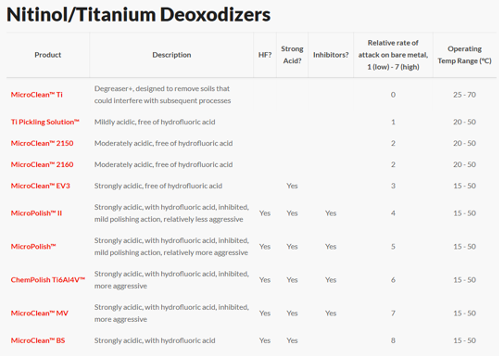

RBP – The Recommended Chemistry for Step 2

At RBP, we have a full range of chemistries for controlled oxide removal during Step 2. We’ve designed our chemistries specifically for the unique challenges of Nitinol heat tint, recast layers, thermal oxides, embedded shop soils, and processing residues formed from laser cutting and shape setting. Through our full product line, we provide you with the correct chemistry that meets your requirements, including:

- Environmental Health and Safety (EHS) considerations

- Specialized inhibitor packages to increase efficacy

- A full range of attacks on metals – from low removal to very aggressive removal

- Robust temperature operating windows

Click here for website link to products above: Medical Implant Device Chemicals | RBP Chemical Technology

What Makes RBP De-Oxidizers/Etchants Stand Out:

✔ Precision Oxide Removal Without Attacking Base Metal: Our chemistries remove oxides and laser recast while protecting the underlying Nitinol, preserving superelasticity and mechanical properties.

✔ Stable & Predictable Etch Rate: Consistency is essential for medical device manufacturing. RBP delivers repeatable performance across:

- High-volume production

- Automated lines

- Tight-tolerance components

✔ Ideal Surface Preparation for RBP’s Room-Temperature Electropolish: Our Step-2 chemistries create a uniform, activated surface that enables:

- Brighter electropolish finishes

- More uniform grain structure

- Enhanced corrosion resistance

- Better fatigue performance

✔ Proven Across Nitinol Device Categories: Trusted for:

- Stents

- Guidewires

- Orthodontic archwires, brackets, implants, and tools

- Staples

- Valves

- Nitinol subassemblies

Unprocessed Processed

Example: Complete scale and oxide removal (post laser cut and heat treat). Part processed with MicroClean EV3 for 5 minutes @ 50 °C (1000x magnification).

No two Nitinol parts are the same, and RBP provides chemistry options for every scenario.

Partner With RBP for a Complete Nitinol Process

RBP has 70 years of surface chemistry expertise, with specialized knowledge in medical device manufacturing. Our technical team helps customers map complete Nitinol processing lines from:

Cleaning → Deoxidizing → Electropolishing → Final Finishing

Whether you’re optimizing an existing line or building a new one, RBP delivers chemistry, process guidance, and technical support that reduce risk and improve outcomes!

15-MINUTE VIRTUAL CONSULTATION

Join our team of chemists and experts via Microsoft Teams to conduct “discovery” of your chemistry process opportunities and challenges.

SEND US YOUR PARTS/PROTOTYPES

We specialize in running your sample parts or prototypes through our in-house chemistry line to find the best solution so you can develop your process.