ElectroPolish 4000™ & 5000™: Unlocking the Science Behind Precision Cleaning and Surface Finishing for Stainless Steel Medical Devices

In the world of medical device manufacturing, form, function, and finish are tightly interconnected. Behind every successful implant, instrument, or surgical tool is a rigorous process that ensures cleanliness, biocompatibility, and long-term durability. One of the most important finishing steps in this process is electropolishing, a precision surface treatment that goes far beyond aesthetics.

In the world of medical device manufacturing, form, function, and finish are tightly interconnected. Behind every successful implant, instrument, or surgical tool is a rigorous process that ensures cleanliness, biocompatibility, and long-term durability. One of the most important finishing steps in this process is electropolishing, a precision surface treatment that goes far beyond aesthetics.

This month, we’re spotlighting ElectroPolish 4000™ and 5000™, RBP Chemical Technology’s specially formulated electropolishing solutions designed to meet the exacting demands of stainless-steel medical components.

What Is Electropolishing, and Why Is It Critical for Medical Devices?

Electropolishing is an electrochemical process that smooths and brightens metal surfaces by selectively removing microscopic peaks on the surface. Unlike mechanical polishing, which can embed particles or deform surfaces, electropolishing removes metal in a controlled, uniform way, perfect for components where surface integrity is requirement-critical.

In medical device applications, electropolishing plays a vital role in:

- Precision Cleaning: Electropolishing removes surface contaminants, burrs, and embedded particles that could harbor bacteria or compromise the integrity of the device.

- Biocompatibility: Smoother surfaces reduce the risk of tissue irritation and improve the interface between medical devices and the human body.

- Enhanced Corrosion Resistance: By removing free iron and promoting chromium oxide formation, electropolishing passivates the metal surface, essential for longevity and reliability.

- Improved Sterilizability: Smoother, cleaner surfaces are easier to sterilize and less prone to contamination.

The Chemistry Behind ElectroPolish 4000™ and 5000™

ElectroPolish 4000™ and 5000™ are engineered to deliver predictable, consistent results across a range of stainless steel alloys and part geometries.

| Product | Best For | Key Benefits |

|---|---|---|

| ElectroPolish 4000™ | General-use stainless steel electropolishing | Higher polishing currents at reasonable voltages, adaptable to many geometries |

| ElectroPolish 5000™ | High-precision medical components | Uniform finish, ideal for parts with tight tolerances and performance-critical surfaces |

Both products use a proprietary aqueous acid mixture that supports high amperage at stable voltages, ensuring a consistent polishing action across the entire component surface.

When to Choose 4000™ vs. 5000™

Think of ElectroPolish 4000™ as your go-to for general electropolishing needs, it’s flexible, fast-acting, and ideal for broad stainless applications.

Meanwhile, ElectroPolish 5000™ is purpose-built for high-spec parts where every micron counts. It delivers ultra-smooth, uniform finishes, exactly what’s required in applications like surgical tools, stents, or orthopedic implants.

Educational Tip: Electropolishing vs. Passivation. What’s the Difference?

While both processes are used to improve corrosion resistance, passivation only removes free iron and oxides from the surface. Electropolishing, on the other hand, actively dissolves a thin layer of metal, resulting in:

- A smoother surface finish

- Deburring and edge rounding

- Superior micro-cleaning and decontamination

That makes electropolishing an ideal first step before passivation or final cleaning in the medical device manufacturing chain.

Real-World Applications

ElectroPolish 4000™ and 5000™ have been used in:

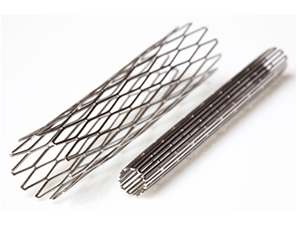

- Orthopedic implants: Ensuring smooth surfaces that interface with bone or soft tissue

- Surgical tools: Enhancing sterilization and performance during repeated procedures

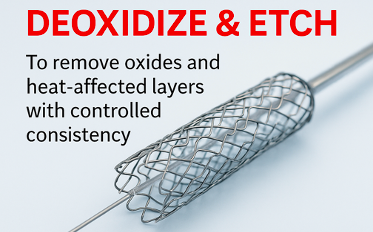

- Catheter components and stents: Removing burrs and debris for safer in-body applications

By refining both the macro and microstructures of the metal surface, these products support precision outcomes where patient safety is at stake.

Final Thought: A Process That Pays Off

Electropolishing is more than a finishing step, it’s a risk reduction measure, a performance enhancer, and a quality control tool all in one. With ElectroPolish 4000™ and 5000™, manufacturers can meet FDA standards more confidently, reduce post-production rework, and deliver cleaner, safer, longer-lasting medical devices.