News and Events

As we wrap up 2024, we want to take a moment to reflect on a truly special milestone for RBP Chemical: our 70th anniversary. This year marked seven decades of innovation, collaboration, and growth, and we could not have done it without the continued support of customers and partners like you.

Fort Carson unveils its groundbreaking battery system, the largest of its kind, marking a significant step forward in sustainable energy innovation for military installations

RBP Chemical Technology, a leading provider of proprietary chemicals and delivery devices for the electronics and defense industries, proudly participated in a recent Lockheed Martin Aeronautics and Engineering Systems (LMAES) event. As one of approximately five select contractors invited, RBP highlighted its cutting-edge electrolytic chemistry solutions that are integral to Lockheed Martin’s advanced defense systems. This is the first fluid battery produced and installed by LMAES.

The demand for high-performance electronics continues to skyrocket, driving innovation in designing and manufacturing Printed Circuit Boards (PCBs). As these components become more complex, the margin for error shrinks. Manufacturers face mounting pressure to enhance production speed, accuracy, and quality while minimizing defects and waste. The right chemical solutions can be critical in optimizing the PCB manufacturing process, leading to improved performance and cost-efficiency. RBP Chemical Technology’s tailored solutions help PCB manufacturers streamline their processes, reduce waste, and meet the most stringent performance standards.

RBP Chemical Technology, a Milwaukee-based leader in developing and delivering proprietary chemicals and devices for diverse industries, has been awarded the 2024 Governor’s Export Achievement Award. Recognized alongside Imbed Biosciences, UW–Milwaukee, and Inpro Corporation, RBP’s award highlights its impactful contributions to Wisconsin’s economy through a steady expansion of exports that extend across North America, Europe, and Asia. Founded in 1954 and celebrating its 70th anniversary this year, RBP continues to uphold its legacy of innovation and commitment to quality, producing advanced surface chemistry solutions in its ISO 9001:2015 certified Milwaukee facility, with additional manufacturing operations in Chennai, India.

Chemistry plays a vital role in medical device manufacturing, ensuring that products are safe, durable, and effective. From sterilization to enhancing materials and ensuring regulatory compliance, chemical processes are critical at every step of device production. As the medical device industry faces increasing regulatory pressure and demand for innovative solutions, chemical advancements are becoming more essential than ever.

RBP Chemical Technology, a renowned supplier of specialty chemicals and delivery devices for the pressroom, printed circuit board (PCB) fabrication, and medical implant device industries, is excited to announce its strategic partnership with Mid-States Graphics, a trusted provider of cutting-edge solutions for professional printers since 1984.

Have you or your organization thought about outsourcing routine or complex chemical manufacturing due to business objectives or strategies dealing with safety, quality, delivery, or cost concerns or opportunities?

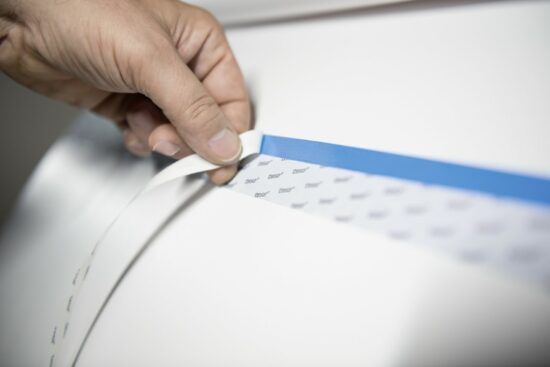

Availability & lead-times of adhesives can be a major issue for print companies, but these marketplace challenges may be coming to an end.

Availability & lead-times of adhesives can be a major issue for print companies, but these marketplace challenges may be coming to an end.

The Problem: In this instance, the affected enterprise was sourcing nitinol electropolish from an overseas supplier. With global supply chain volatility, tariffs, and freight backlogs and non-availability, the enterprise faced stock-outs, quality issues, and economic hardships from their current supplier.

It is common to electropolish Nitinol parts in a solution of sulfuric acid and methanol cooled to subzero temperatures, typically -30˚C to -50˚C. This works, and it almost considered a standard method of electropolishing Nitinol and similar materials. But working at these low temperatures is difficult. Powerful chillers are needed. It takes time to cool the solution. Condensation issues and icing around the EP vessel need to be addressed.