News and Events

Users of chemical treatment baths often ask for controls that guarantee a steady process and also allow to maximize the utility of the bath. How can we measure that the bath is the same and how do we know when it should be replaced? Well, such guidelines are difficult to be had for a couple of reasons. First, parts are not standardized, and 1 cm2 of surface of a certain Nitinol part is likely different from 1 cm2 of surface of another part (even if we are able to measure the surface area). Then, in many cases the analytical tests that would be required are complex, require chemical expertise and/or training, and sometimes advanced instrumentation. We would like the simple pH measurement to do the trick but it can’t. An acid titration? More complicated and it would give better information; but still not very usable. A fluoride concentration measurement, using a fluoride ion selective electrode, is much better but the complexity of the measurement goes up significantly. Then, perhaps water concentration is important to measure in electropolishes – this needs a specialized Karl Fischer titrator with special reagents and careful maintenance. For dissolved metal (example: nickel and titanium) we need an ICP-OES or an equivalent spectrophotometer. So the pH measurement is easy and quick but not very useful, the other more useful controls require expensive instrumentation, expertise, maintenance, and each test takes longer time. This is the reality. Yes, this all can be done, but is it worth it? The answer so far seems to be “no” from many of our customers. And the adopted process (SOP) often describes the bath control like this: run 20 stents per liter and then replace with new (example).

It is well-known that for etching (a.k.a. pickling, deoxidizing) titanium and its alloys, including Nitinol, one can use chemical mixtures containing hydrofluoric acid, HF. It also well-known that it is a relatively dangerous substance. Some medical device companies outright ban such HF-containing chemistries. There are alternatives, which work well in many cases. Those alternative chemistries contain another “fluoro” substance, named fluoroboric acid. The latter is much safer, because it does not release fluoride ion at the same concentration as hydrofluoric acid. Fluoroboric acid, HBF4, contains “bound” fluoride and has to undergo hydrolysis to yield fluoride: BF4– + H2O <-> H+ + (OH)BF3– + F–. This equilibrium reaction is shifted significantly to the left, meaning that a decent concentration of BF4– will produce little F–. This is different from HF, which is essentially the same as F–, at the same high concentration. A simple confirmation of this is a measurement of fluoride concentration with fluoride ion selective electrode (ISE). Two solutions with similar concentrations of hydrofluoric acid and fluoroboric acid show ~100 times less fluoride in the latter. Yes, one can use very very diluted solution of HF to obtain the same fluoride concentration. But it won’t be exactly the same situation: fluoride from the dilute HF solution will be consumed quickly but the fluoride from HBF4 will be replenished through the equilibrium reaction above (Le Chatelier’s Principle) and decrease at a much lower rate.

In one project we were tasked with improving a process of removing a scale/debris from laser-cut CoCr parts. It became apparent that, while CoCr is corrosion-resistant (meaning: chemically-resistant) the scale was even harder to attack. Only very aggressive chemistries worked and they had to be mixed fresh on-site, because they were reactive and unstable over time. For us, the chemical vendor, such situations present a challenge – we want a product with a decent shelf-life, stable over time. And we did not have a product for this customer at the time. However, sometime later, through experimentation, we developed a new product: CoCr Cleaner II, which is stable to ship and store, yet cleans the CoCr scale quite well.

It is a bit complicated.

Ideally, we would like to use a chemical solution that can dissolve the oxide layer and do so uniformly without attacking the base metal (meaning: we want high oxide-to-metal selectivity of the deox chemical). In reality: a) some oxides are sluggish to dissolve, and b) some areas of the part clear oxide sooner and the chemicals begin to etch the metal.

- SS beaker/tank or glass/plastic vessel with a SS cathode

- To maintain EP temperature; high capacity for low temperature electropolishing and lower capacity for room temperature electropolishing

- For less conductive EP solutions higher voltage range is necessary

- Magnetic stirring is convenient and easy; other means of exerting solution flow may offer more uniformity

- Part-dependent; SS wires or forceps are convenient; titanium and some specialty alloys will draw less current

What advantages can you gain in your business from following our recommendations?

We can help you – contact us to find out more.

Ernie Litynski, President, RBP Chemical Technology

MILWAUKEE, Wisconsin — RBP Chemical Technology and Lighteum have entered into a collaborative partnership focused on Nitinol device development and processing. Recognizing that each company brings best-in-class technical capabilities in their areas of expertise, coupled with a spirit of openness and cooperation, it became quite apparent that the two companies should formalize their working relationship.

A few years ago, a partner came to us with a difficult assignment. They were producing a mix of a volatile acid, something like 99% sulfuric acid with an alcohol solvent, in house. They needed to reduce the cost of producing and storing this chemical while also lowering risks to their employees.

A few years ago, a partner came to us with a difficult assignment. They were producing a mix of a volatile acid, something like 99% sulfuric acid with an alcohol solvent, in house. They needed to reduce the cost of producing and storing this chemical while also lowering risks to their employees.

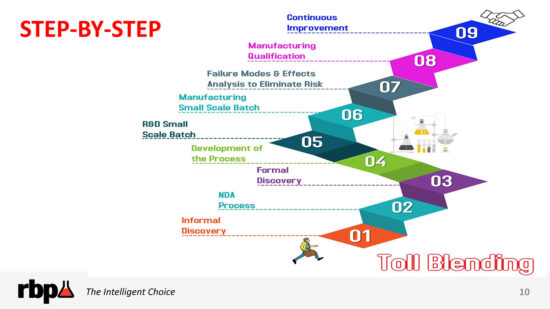

We get asked this question all the time: How does it work if I really want to outsource some of my chemical manufacturing to a toll blender? Toll Blending is a common service for chemical companies (e.g.: “toll blender”) to manufacture/fulfill chemistry blending for a partner to reduce the partner’s production risks or capital investments. RBP Chemical Technology works with partners around the globe to provide this service, as well as, to optimize their chemical processes.

We get asked this question all the time: How does it work if I really want to outsource some of my chemical manufacturing to a toll blender? Toll Blending is a common service for chemical companies (e.g.: “toll blender”) to manufacture/fulfill chemistry blending for a partner to reduce the partner’s production risks or capital investments. RBP Chemical Technology works with partners around the globe to provide this service, as well as, to optimize their chemical processes.

SAN DIEGO, California — RBP Chemical Technology, known for consistently delivering high-quality products and services, based in Milwaukee, Wisconsin announced their exclusive partnership today with Schlötter GmbH based in Geislingen, Germany.

Toll Blending is a common service for chemical companies (e.g.: “toll blender”) to manufacture/fulfill chemistry blending for a partner in order to reduce the partner’s production risks or capital investments. RBP Chemical Technology works with partners around the globe to provide this service, as well as, to optimize their chemical processes. Here are six reasons why customers turn to RBP for their toll blending needs.